Let’s find a custom solution together.

Smaller voids and lower costs

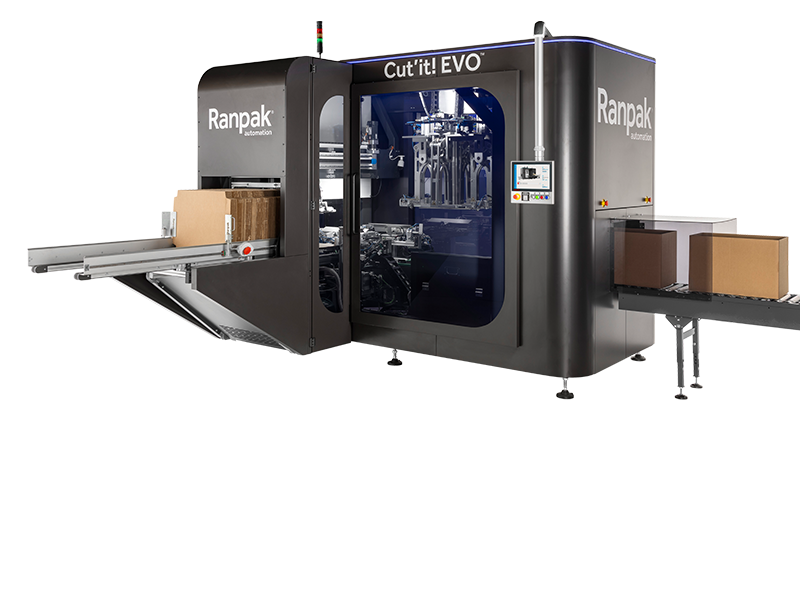

The Cut’it!™ EVO automated in-line packing machine reduces voids in parcels before shipping, cutting down on shipping costs. It automatically shortens cartons to match their highest point of filling, and then glues a lid securely in place.