Let’s find a custom solution together.

The custom packaging material delivery solution

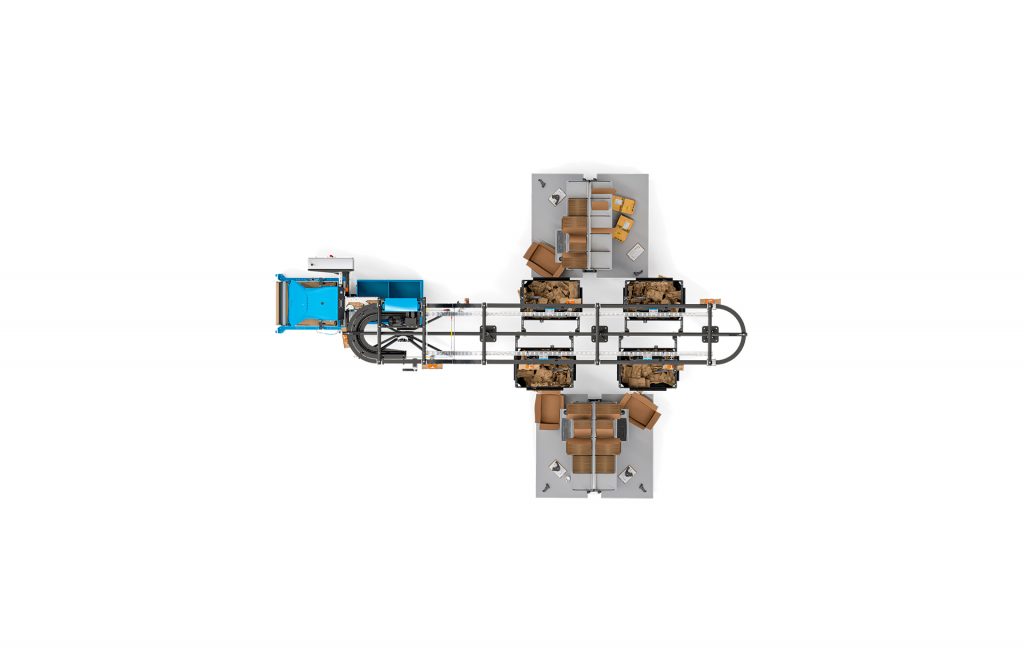

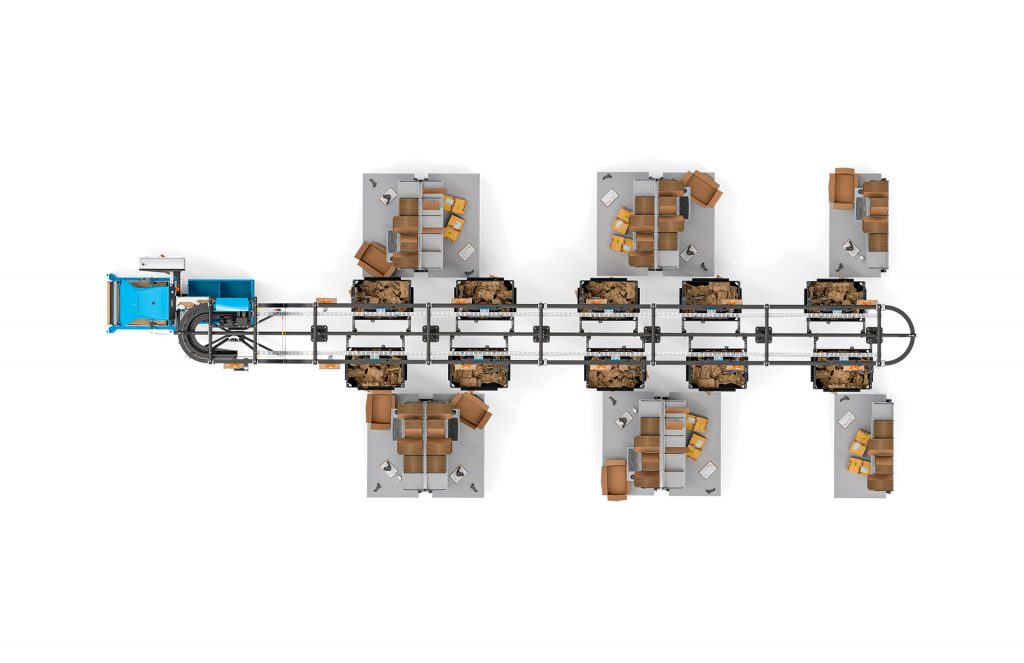

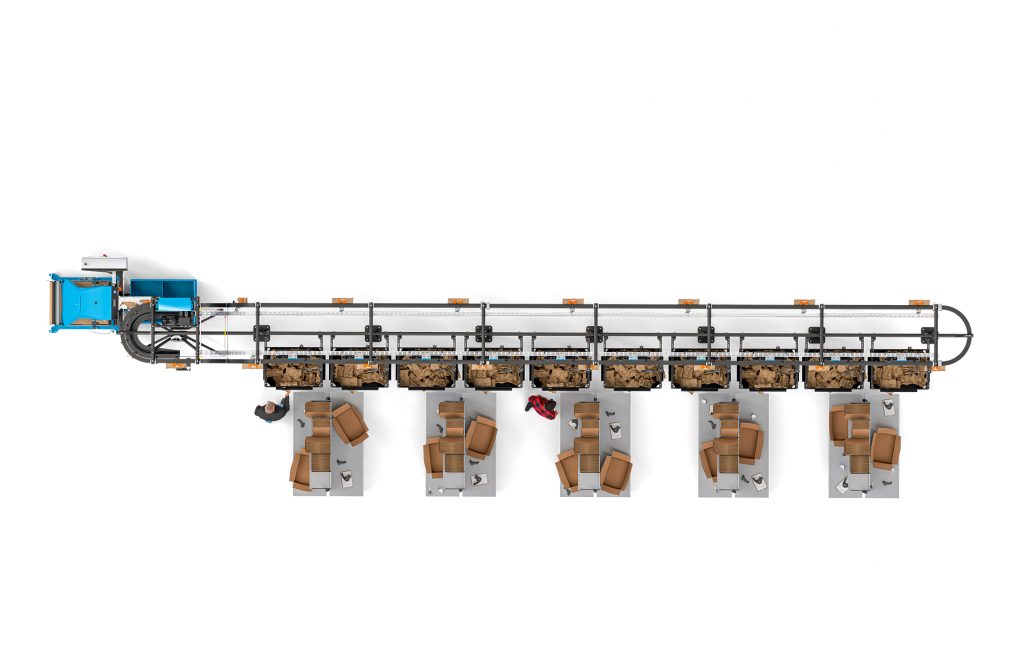

Space comes at a premium within many busy packaging environments. The PadPak® Multi-Station solution allows a single central converter to supply a steady stream of paper cushioning pads to each packing station along a line, supporting continuous automated pad distribution. The system addresses the challenges created by a lack of space, including higher labor and fixed costs, wasted time spent walking around a packing area, and the risk of repeated injuries from cramped working conditions.