Let’s find a custom solution together.

AI machine vision for optimal end-of-line packaging

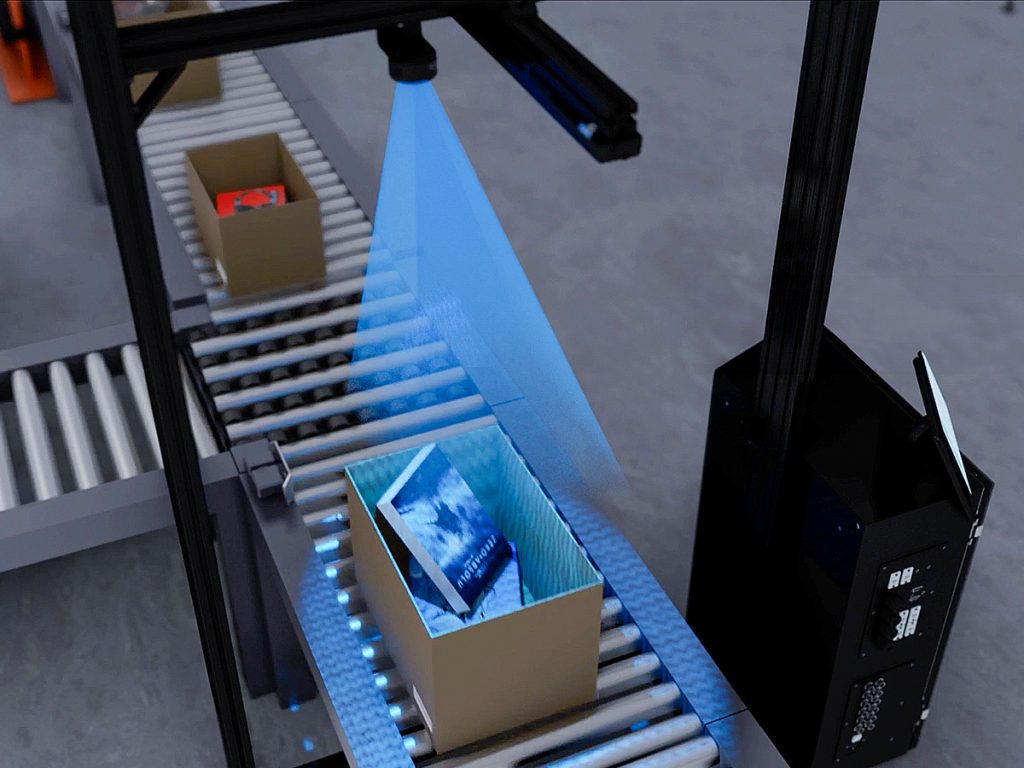

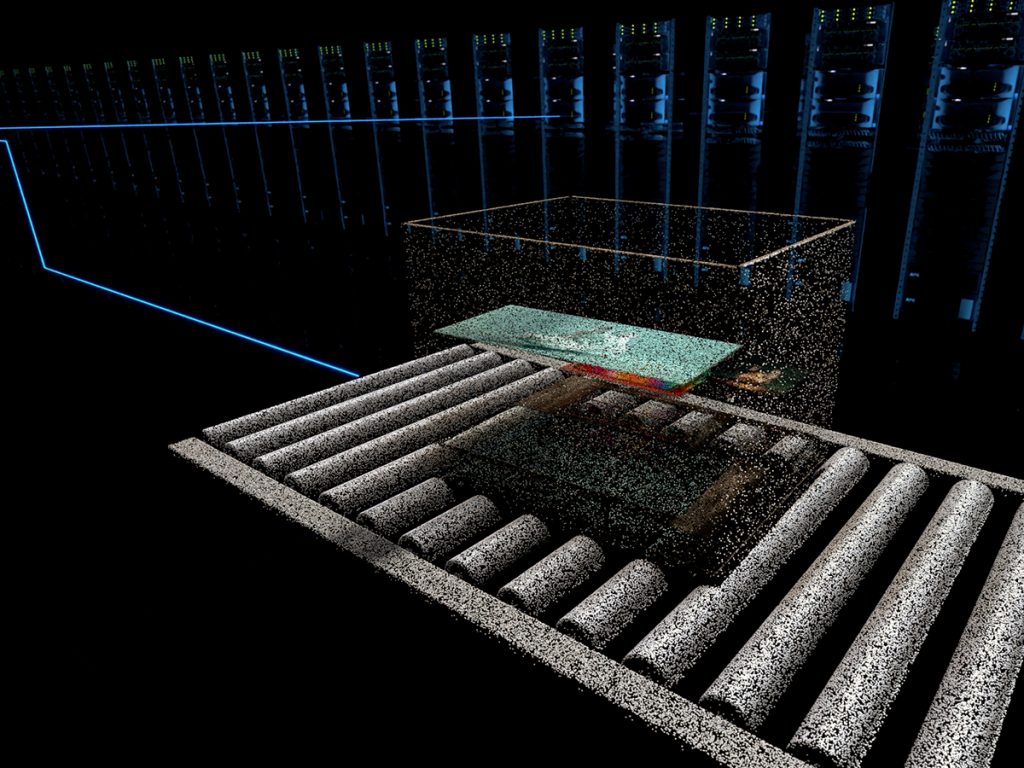

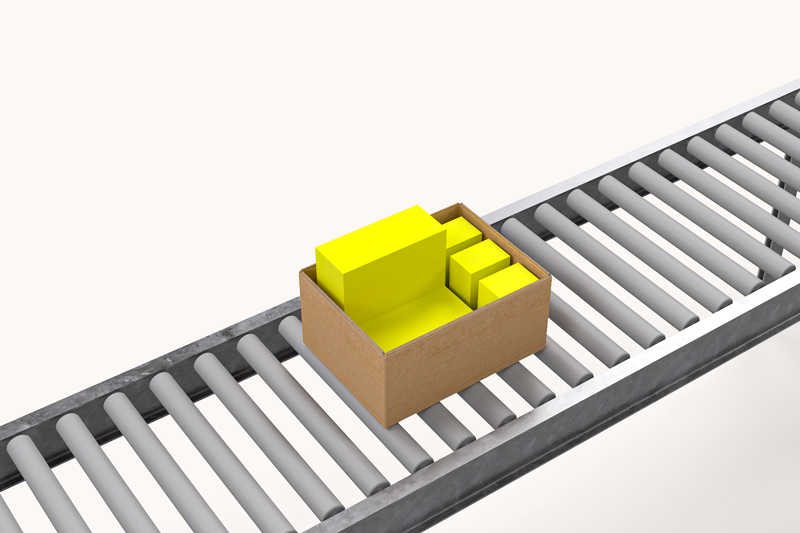

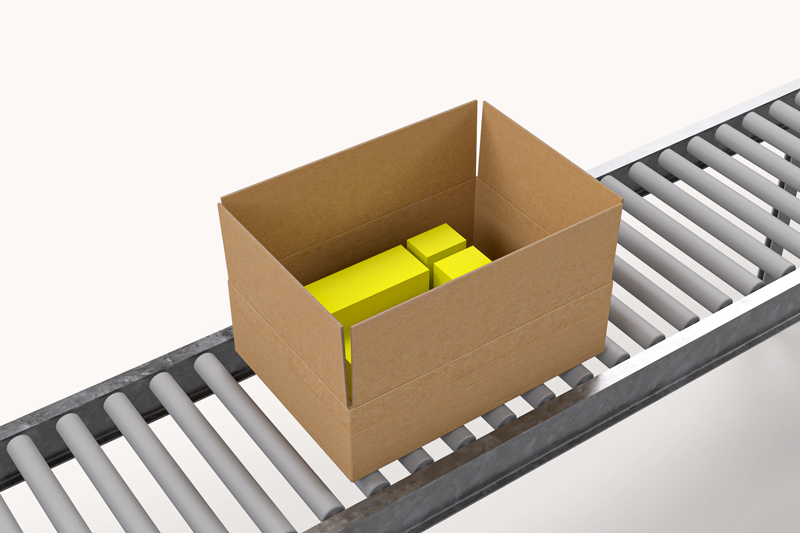

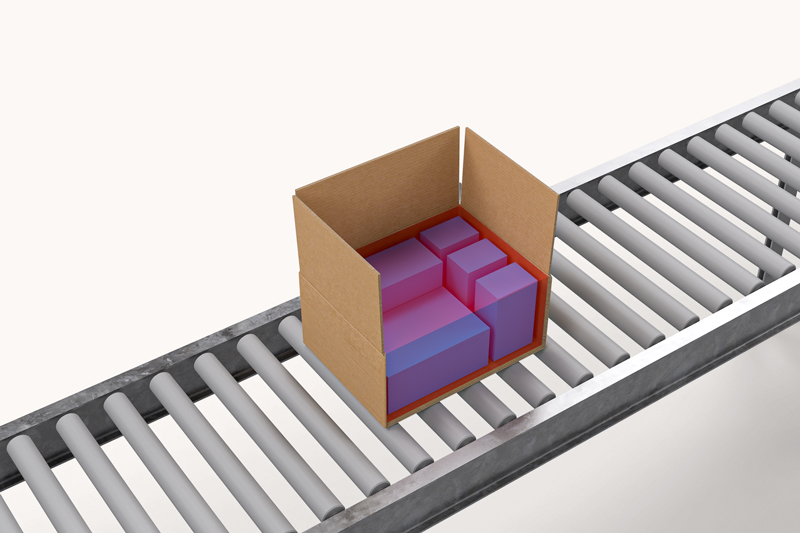

Your business loses time and money every time a packaging machine jams, which makes minimizing downtime and boosting throughput crucial to optimize productivity. AI and machine vision can help. Ranpak’s DecisionTower™ uses AI to detect out-of-scope boxes, which both optimizes packing and prevents machine stops to help you realize unrivaled ROI.

It not only reduces reliance on end-of-line operators for quality control, but also captures data to prevent future errors from rough handling or faulty packaging. DecisionTower uses AI to maximize equipment uptime, customizing processes for your business.